Do you know how to maintain the optical fiber fusion machine. Today, TUMTEC teaches you five ways to maintain the fusion splicer.

There are five main ways to maintain the fusion splicer. It is generally recommended that the electrode be cleaned 400 to 500 times by discharge splicing and replaced after 7000 times of discharge.

Please try to use the original electrode to improve the splicing quality.

First: The splicing machine we provide is equipped with a set of cleaning tools. When cleaning the electrodes, the electrodes are cleaned with cleaning tools. For detailed cleaning methods, please refer to our operating manual. If the discharge is not normal after cleaning, the electrodes need to be replaced. In general, the electrodes need to be cleaned after 500 times of splicing, and new electrodes need to be replaced after 7000 times of using. When replacing the electrodes, please use the original electrodes provided by us. With other electrodes, we can not guarantee the normal operation of the splicing machine, which may damage the splicing machine. During the splicing process, the welder shows that "no optical fibers can be found or the end face of the optical fibers is untidy".

Second:The splicing machine is mainly caused by the surface contamination of the optical system. The glass sheet should be cleaned and protected by anhydrous alcohol.

At the bottom of the pole, the lens on the pressure cap is cleaned at the same time. Wait until the alcohol has dried up before splicing.

The main cause of this situation is the dirt in the V-groove. OTDR maintenance needs to clean the V-groove. When cleaning, use absolute alcohol to clean, use toothpick or high pressure gas to clean the stolen goods in the trough, and pay attention to not using hard objects to clean the V-shaped trough. In this way, it is easy to cause damage to the V-shaped trough.

Third: During the splicing process, the abnormality of the fusion part of the optical fibers and the uneven discharge of the electrodes were found.

This is mainly due to the oxidation of the tip of the electrode and the existence of oxide at the tip, which makes the discharge part of the electrode uniform, resulting in poor splicing quality.

The electrodes need to be cleaned.

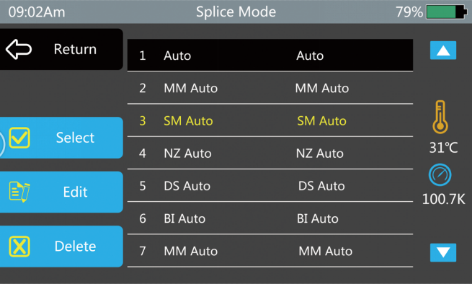

Fourth: splicing machine prompts clean electrodes.

This is due to the setting of reminder cleaning electrodes in the fusion splicer. When the reminder cleaning electrodes appear in the welder electrodes and batteries, please clean the electrodes. At the same time, the parameters can be changed in the parameter setting of the fusion splicer.

Fifth: Reduced battery life

Our fusing machine batteries are just like the cell phone batteries we use. We also need to pay attention to the use of batteries. Usually, the capacity of batteries is 30%.

When above, please use the battery as much as possible to supply power. At the same time, please note that when AC power supply is used, the batteries of the fusion splicer will be charged at the same time.

When it is found that the service time of the battery decreases, the battery can be charged and discharged three times in depth so that the service time of the battery can be prolonged.

Once the battery is quickly charged and the working time is shorter, please charge and discharge three times. If the failure can not be eliminated, it shows that the battery life has reached the limit, the original charging battery needs to be replaced and the battery needs to be replaced.

Links

Magic Lamp