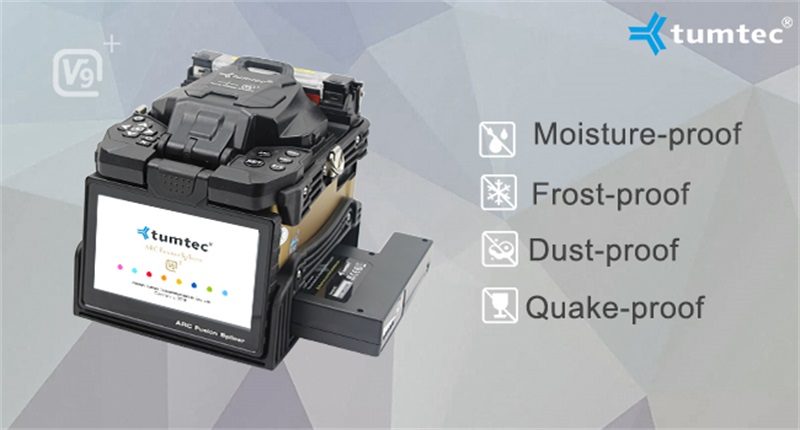

We know that tunmtec splicing machine has superior performance: 3 seconds starting, 6 seconds splicing, 15 seconds heating, 500 times focusing magnification, stable splicing effect (0.01-0.03dB loss), low energy consumption, excellent performance of four (moisture-proof, dust-proof, shock-proof, frost-proof), tumtec brand is worth believing in.

Yesterday, Baidu AI developer Yanhong Li explained Baidu's exploration and progress on AI on the stage. When he was speaking, he was splashed water. How to deal with the unexpected situation in his speech? In the face of unexpected circumstances, some people may embarrass the scene and have to leave early, but he calms down, quickly adjusts his state, smiles at the audience and continues to speak. His proper emergency treatment shows how high his comprehensive quality level is.

Something that goes wrong always goes wrong; if you're worried about something, it's more likely to happen. No matter how many times we prepare in advance, we can never completely avoid accidents.

Splicing machine will inevitably break down because of improper use and other reasons. What will you do when the welder breaks down? Yanhong Li was calm and steady, and the performance of tumtec splicing machine was very stable. Come in and have a look. Today we will answer your questions.

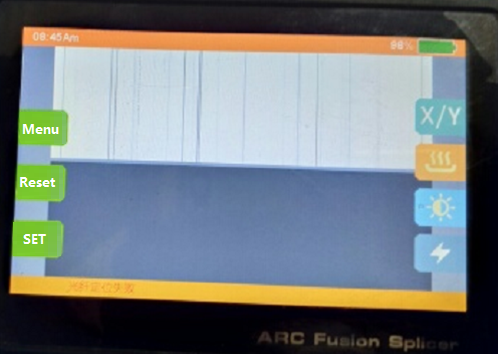

(1)Failure performance: X/Y face painted or white screen

Solution: Replace cmos cable or cmos board

(2)Failure performance: X/Y black screen

Solution: Replace the red light

(3)Failure performance: Both sides of X/Y are black

Solutions:

1、Replace red light

2、Rotate or replace hall sensors

3、Check whether the magnet on the left side of the windproof cover is assembled in the wrong direction (if the magnet cannot be replaced, only the windproof cover can be replaced).

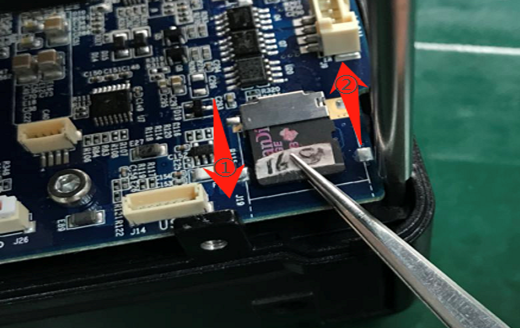

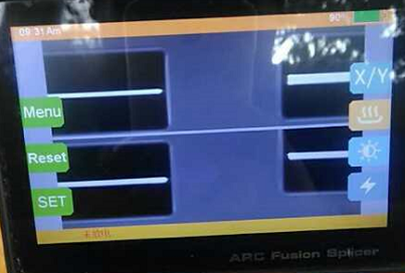

(4)Fault performance: Boot red and blue light on

Solution: Clean and unplug SD CARDS. (as shown in figure)

(5)Fault performance: Fiber around the size of different

Solution:

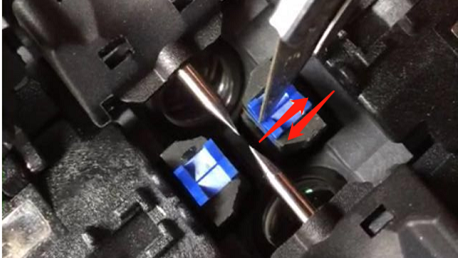

Clean the v-groove

Check if the hammer is pressed on the line groove

(6)Failure performance: Often locked

Solution: Contact the manufacturer,software unlock ,replace the mainboard

(7)Failure performance: No display and white screen

Solution: Replace LCD or monitor driver panel

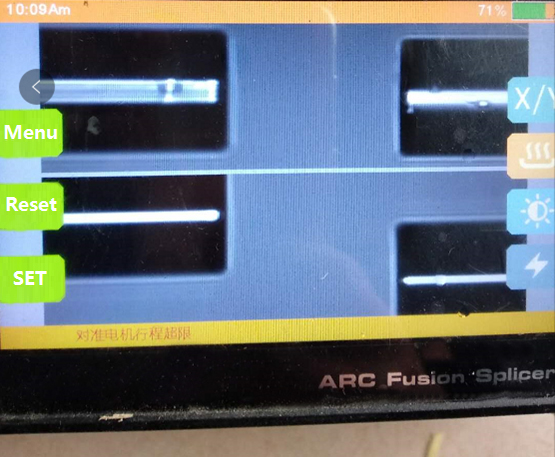

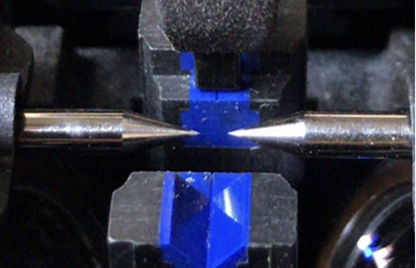

(8)Fault performance: Tip for left and right optical fiber end face contact during welding

Solution:Replace the fixture or cmos board;Clean the lens surface;

(9)Failure performance: welding indicates non-discharge

Solution: Replace the main board or the pressure pack.

(10)Failure performance: When the optical fiber is pushed out, the two ends of the optical fiber are constantly hitting.

Solution:

Clean lens surface

Check whether the cmos board has watermark and dirty spots.

Check if the pressure hammer is in position.

The best way to understand a welding machine is to see how it responds to accidents...want to know more about splicing machine,click here.

Links

Magic Lamp